#SustainableisSmart

Sustainable Manufacturing in the Age of Industry 4.0 and Smart Manufacturing

Overview

Benefits

Readiness

Success Stories

Talk to Us

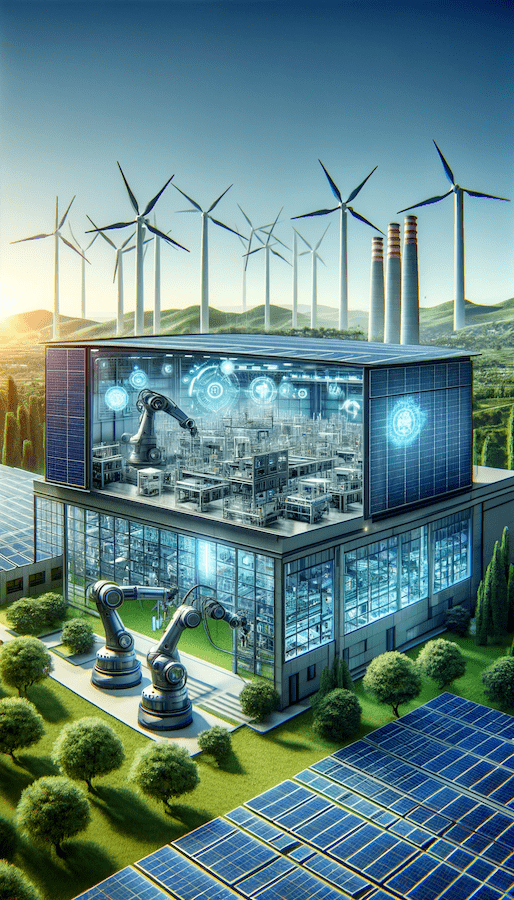

Sustainable Manufacturing in the Age of Industry 4.0 and Smart Manufacturing

Sustainable manufacturing transcends the scope of Industry 4.0 and smart manufacturing by integrating environmental and social responsibility into the core of manufacturing processes.

While Industry 4.0 and smart manufacturing primarily focus on technological advancements and efficiency improvements, sustainable manufacturing encompasses a broader, more holistic approach.

The challenges of sustainable manufacturing often drive innovation in product design, materials, and production processes. Companies leading in sustainability can gain a competitive advantage by pioneering new, more efficient, and eco-friendly products and solutions.

Benefits that build resilience

Reduced Environmental Impact

Sustainable manufacturing minimizes waste, reduces energy consumption, and lowers greenhouse gas emissions. Technologies like predictive maintenance and energy-efficient machines from Industry 4.0 help in optimizing resource usage.

Long-Term Viability

While Industry 4.0 improves current processes, sustainable manufacturing looks at the long-term implications of production. It ensures that the manufacturing practices of today do not compromise the ability of future generations to meet their needs, thereby promoting intergenerational equity.

Increased Efficiency and Productivity

By focusing on resource efficiency and waste reduction, sustainable manufacturing can lead to significant cost savings over time. This approach helps in creating an economically sustainable business model that can withstand resource shortages and shifts in market demands.

Resilience and Adaptability

Sustainable manufacturing practices often involve diversifying energy sources, using renewable materials, and implementing closed-loop systems. These practices make companies more resilient to changes in resource availability and market conditions.

Are you ready to move to the promise of Sustainable Manufacturing?

Assessing readiness to transition to sustainable manufacturing is a multi-faceted process that requires a thorough evaluation of various aspects of an organization. Here are the top five critical factors to consider:

Organizational Commitment and Leadership Support

The transition to sustainable manufacturing must be driven by strong commitment and support from the top levels of the organization. This includes the willingness of leadership to invest in sustainable practices and to integrate sustainability into the core business strategy.

Technological Capability and Infrastructure

Sustainable manufacturing often requires advanced technologies such as renewable energy sources, energy-efficient equipment, and smart manufacturing systems aligned with Industry 4.0 principles.

Financial Resources and Investment Capacity

Transitioning to sustainable manufacturing can involve significant initial investment in new technologies, process redesign, training, and infrastructure changes.

Supply chain and Sourcing Practices

Sustainable manufacturing extends beyond the confines of the company and involves the entire supply chain, including sourcing of raw materials, logistics, and distribution.

Regulatory Compliance and Industry Standards

Compliance with environmental regulations and industry standards is a critical aspect of sustainable manufacturing.

Strong Partner with Engineering and Technology Expertise

A strong partner can make the seamless transition from your current state to the promised land of sustainable manufacturing. The partner must come with the DNA of manufacturing, technology expertise and an equal passion for sustainability.

Success Stories

Sustainable Manufacturing Consulting

Get your sustainable manufacturing journey right, the first time